Project type:

Lightweighting

Project name:

Virtual Twin Lightweighting

Project aim:

To develop a coating that will enable glass containers to be lighter without compromising strength and shape.

Key benefits:

The Virtual Twin project is developing a coating that enables glass containers to be lighter, without compromising strength and shape.

Description:

This R&D lightweighting project between Ardagh Group, Exxergy, Dassault Systèmes and Diageo, aims to develop a coating that will enable glass containers to be lighter without compromising strength and shape. The external coating will reduce naturally-occurring micro-cracks in the glass surface, allowing the glass to be much lighter while maintaining its strength.

Project type:

Renewable Electricity - Solar

Project name:

Onsite solar energy at AGP-Irvine

Project aim:

An onsite solar installation producing renewable electricity for the AGP-Irvine facility.

Key benefits:

This onsite solar installation is expected to remove the equivalent of c. 356 tonnes of CO2 annually.

Description:

An onsite, rooftop 1.75 Megawatt Peak solar PV installation of 3842 panels at AGP-Irvine in Scotland is generating onsite renewable electricity, which will add enough electricity back to the grid to remove the equivalent of an estimated 356 tonnes of CO2 annually.

Project type:

Battery Project

Project name:

Electricity storage AGP-Irvine

Project aim:

Provide AGP-Irvine with reliable year-round energy for continuous glass production using sustainable battery storage, increasing resilience and energy security.

Key benefits:

This Tesla battery system ensures reliable back-up during peak energy use and returns energy to the grid during low demand.

Description:

Ardagh Glass Packaging implemented Europe's largest behind-the-meter storage system, a Tesla Battery Storage System. This innovative solution not only provides a reliable backup during peak energy consumption but also feeds energy back to the grid during low demand.

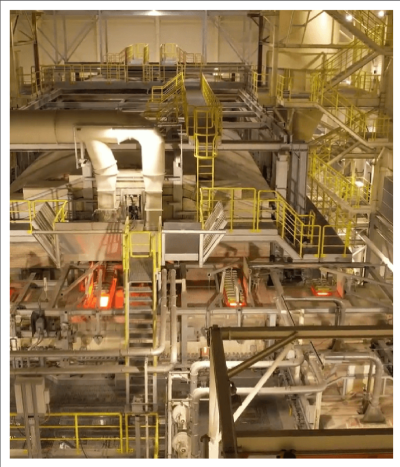

Project type:

Efficient Furnace

Project name:

Efficient Furnace AGP-Doncaster

Project aim:

To build a highly sustainable 'Efficient Furnace' that will minimise greenhouse gas emissions from the glass production process.

Key benefits:

This efficient furnace significantly reduces gas consumption, reducing carbon emissions by 14% compared to the previous furnace.

Description:

This state-of-the-art furnace at AGP-Doncaster, UK, uses the latest conventional furnace technology with a more efficient melter, significantly lowering gas consumption and carbon emissions. It includes a gas filtration process with advanced filters to reduce other emissions well below industrial standards, reducing CO2 by 14% compared to the old furnace.

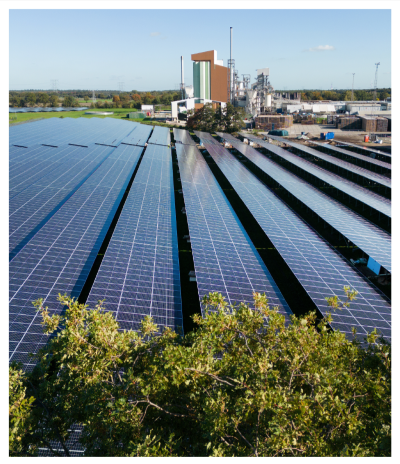

Project type:

Renewable Electricity - Solar

Project name:

Renewable electricity at AGP-Moerdijk

Project aim:

A solar installation producing renewable electricity for the AGP-Moerdijk facility.

Key benefits:

This solar installation is expected to reduce the carbon footprint at AGP-Moerdijk by c. 725 tonnes of CO2 annually.

Description:

AGP's solar installation in Moerdijk, the Netherlands, is expected to generate over 2,500 MWh of electricity per annum, reducing the facility's carbon footprint by an estimated 725 tonnes of CO2 annually.

Project type:

Renewable Electricity - Solar

Project name:

Renewable electricity at AGP-Dongen

Project aim:

A solar installation producing renewable electricity for the AGP-Dongen facility.

Key benefits:

This solar installation is expected to generate over 8000MWh of renewable electricity annually at AGP-Dongen.

Description:

The solar installation at Ardagh Glass Packaging in Dongen, the Netherlands is expected to generate over 8000 MWh of electricity per annum - a significant step in achieving AGP's target to use 100% renewable electricity by 2030.

Project type:

Renewable Electricity - Solar

Project name:

NextGen Furnace PPA

Project aim:

To secure a long-term supply of 100% renewable energy for AGP's NextGen Furnace.

Key benefits:

This Power Purchase Agreement will secure a solar energy supply of c. 130GWh to AGP's NextGen Furnace.

Description:

AGP-Europe has entered a PPA with Sunnic Lighthouse to secure a longer-term solar energy supply to AGP's NextGen Furnace in Obernkirchen, Germany, with an annual volume of approximately 130GWh.

Project type:

Next Gen Furnace

Project name:

Next Gen Furnace

Project aim:

To reduce CO2 emissions by operating with up to 80% renewable electricity at the AGP-Obernkirchen facility in Germany.

Key benefits:

The Next Gen Furnace has reduced carbon emissions by 64% per bottle to June 2024.

Description:

AGP's breakthrough Next Gen Furnace has reached a consistent 64% CO2 emissions reduction in 2024, and AGP is striving for more. The CO2 reduction has been achieved by reaching an average rate of 60% electrical heating in the furnace, and has saved approximately 18,000 tonnes of CO2 from January to June 2024.

Project type:

STEM Project

Project name:

Ardagh for Education (Germany, also active in North America, Brazil, and Africa)

Project aim:

Ardagh for Education's mission is to give back to our communities through quality STEM education, empowering future generations with 21st-century skills by upskilling educators.

Key benefits:

Ardagh for Education trains teachers and provides students with high-quality STEM learning experiences to equip them with in-demand, 21st century skills.

Description:

Ardagh for Education, a STEM program, enhances teachers' skills through quality training and provides students with hands-on learning to develop 21st-century skills like problem-solving, collaboration, critical thinking and more. To date in 2024, the program has engaged 129 schools in Germany, upskilled 301 teachers and 23 ambassadors, and reached over 6,000 students.

Project type:

Efficient Furnace

Project name:

Efficient Furnace AGP-Germersheim

Project aim:

To build a highly efficient regenerative furnace, to minimise carbon emissions from the glass production process.

Key benefits:

AGP-Germersheim's efficient regenerative furnace aims to reduce carbon emissions by c. 23%.

Description:

A conversion from recuperative to regenerative furnace technology, reducing carbon emissions by 23%.

Project type:

Water reduction

Project name:

Water Reduction Project

Project aim:

To deliver a reduction in water usage.

Key benefits:

Closed loop systems replace the use of local groundwater to cool the IS machines, with a 25% reduction in water usage.

Description:

Independent closed loop systems have been installed for clean and dirty water, in place of using local groundwater, to cool the IS machines, delivering a 25% reduction in water usage compared with 2021.

Project type:

Efficient Furnace

Project name:

Efficient Furnace AGP-Wyszkow (Furnace 1)

Project aim:

To build a highly efficient regenerative furnace and to minimise carbon emissions from the glass production process.

Key benefits:

AGP-Wyszkow's efficient regenerative furnace aims to reduce carbon emissions by c. 34%.

Description:

A conversion from recuperative to regenerative furnace technology, reducing carbon emissions by 34%.

Project type:

Hydrogen Project

Project name:

Hydrogen Electrolyser AGP-Limmared

Project aim:

To replace 20% natural gas in the furnace with green hydrogen, reducing the carbon footprint of Absolut glass bottles by 17%.

Key benefits:

By replacing 20% natural gas in the furnace with green hydrogen, the carbon footprint of Absolut glass bottles will be reduced by c. 17%.

Description:

AGP has partnered with Absolut to replace 20% natural gas with green hydrogen in the furnace at the AGP-Limmared facility in Sweden. By installing a hydrogen electrolyser onsite, AGP will produce a continuous supply of green hydrogen to the furnace. It aims to reduce the overall carbon footprint of glass containers by approximately 17%, saving approximately 5,000 tonnes of CO2 each year.

Project type:

Renewable Electricity - Wind

Project name:

PPA for wind-generated renewable electricity

Project aim:

To secure a supply of 100% renewable energy for AGP's European operations.

Key benefits:

The Sweden wind-generated renewable energy project will cover c. 40% of AGP-Europe's power load.

Description:

AGP has entered a ten year renewable energy PPA with RPC's 161MW Vitberget wind project in Sweden. It will cover approximately 40% of AGP-Europe's power load and is an incremental step towards achieving AGP's goal of transitioning to 100% renewable electricity by 2030.

Project type:

Water reduction

Project name:

Closed Loop Water Cooling Process

Project aim:

To deliver a substantial reduction in surface water usage.

Key benefits:

The Closed Loop Water Cooling system replaces water with air to cool down the production process. This reduces water usage.

Description:

By installing a two-step, closed-loop, air and water-cooling system, air replaces water previously taken from the nearby river, to cool down the production process, delivering a 66% reduction in surface water usage compared with 2021.

Project type:

Renewable Electricity - Solar

Project name:

VPPA Bulgaria

Project aim:

To deliver a substantial reduction in surface water usage.

Key benefits:

To secure a long-term supply of renewable electricity with a solar photovoltaic project in Bulgaria, securing renewable electricity for AGP's glass manufacturing operations across Europe from April 2026.

Description:

The VPPA - one of the first to be signed in Bulgaria - is intended to provide 110 GWh per year of renewable electricity to AGP-Europe, over 12 years. It complements AGP-Europe's renewable energy supply from wind power, secured in Sweden early in 2024. Together, thanks to their different sources, they are designed to provide AGP-Europe with a consistent renewable power supply throughout the year.

- Regions - Americas

- Our markets

- Innovation

- Catalog

- Careers

- Regions - Europe

- Our markets

- Decoration

- Innovation

- Catalogue

- Regions - Africa

- Our markets

- Clarity Digital Magazine

- Innovation

- Catalogue

- Careers

- money4glass