Protecting our environment

Through the Emissions and Ecology pillars of our sustainability strategy, we take a strategic approach aimed at reducing negative environmental impacts within our direct operations and value chains. Use the contextual menu on this page to navigate through the different sections and learn more.

Emissions

Reducing greenhouse gas emissions is a key focus of our sustainability strategy. At AGP, the focus is on reducing GHG emissions, while at AMP the focus is on reducing GHG and VOC emissions. We have approved SBTi targets, ensuring our goals are consistent with the latest climate science. Achieving our 100% renewable electricity goal will be a critical step towards achieving our emissions targets.

Glass and aluminum circularity, alternative fuels like hydrogen and biogas will all contribute to us reaching our targets. By taking a tailored approach to each operating business’s emissions profile, we are driving meaningful progress toward our SBTi targets

2030 AMP status to targets

reduction

14% increase from 2020

14% increase from 2020reduction

reduction

At AMP, GHG emissions are predominantly within scope 3, accounting for approximately 90% of the total emissions in 2023. As an aluminium converter, our focus is on reducing emissions within our supply chain by collaborating with partners to drive more sustainable practices. We’ve already seen significant results in reducing our scope 3 emissions due to utilising metal coils with a lower carbon footprint, primarily through increased recycled content, as well as optimising metal coil use through product lightweighting and downgauging.

1 The Research Institute of Sweden (RISE) provided limited assurance of the acquisition, processing and aggregation of the quantitative data necessary to calculate the principal 2023 environmental and health & safety KPIs reported. 2 Based on current best available data and calculation methodology. We continuously assess and review our methodologies and the strength of our data sets. 3 Intensity metrics shown include can body production facilities only (excluding Huron, Ohio – since this facility produces both cans and ends), as water and VOC emissions from ends production is insignificant.

2030 AGP status to targets

reduction

reduction

NextGen Project Spotlight: Glass manufacturing is an energy-intensive process. AGP is meeting this challenge head-on with its innovative NextGen Furnace,

designed to run predominantly on renewable electricity, supplemented by natural gas. This hybrid approach significantly lowers the carbon foorprint of glass packaging production, marking a major step toward more sustainable manufacturing.

1 The Research Institute of Sweden (RISE) provided limited assurance of the acquisition, processing and aggregation of the quantitative data necessary to calculate the principal 2023 environmental and health & safety KPIs reported. 2 Based on current best available data and calculation methodology. We continuously assess and review our methodologies and the strength of our data sets.

Visit our sustainability publications to find out more

Decarbonisation roadmaps

The decarbonisation roadmaps below illustrate a potential pathway toward achieving our approved science-based targets. They highlight key enablers and provide insights into the strategies and technologies we may adopt to advance our sustainability ambitions by 2030. Click here to view the full roadmap.

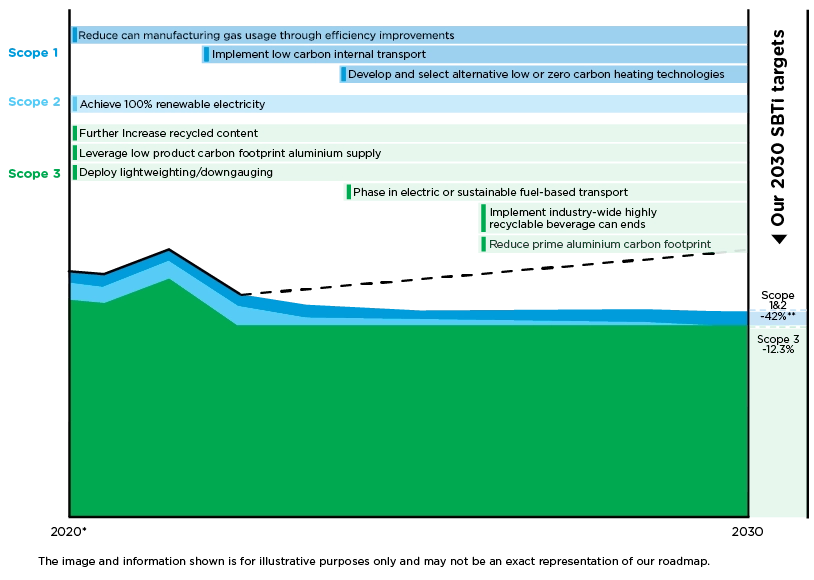

AMP roadmap towards our science based targets

We aim to achieve our 2030 emissions targets through a broad range of actions outlined below while setting the foundations for further decarbonisation beyond 2030.

*Baseline figures for emissions are from 2020

**Scope 2: 100% renewable electricity by 2030

—— Projected business as usual

At AMP, we are committed to our sustainability goals and progressing toward our 2030 SBTi targets. Key levers for decarbonising are increasing recycled content in aluminium and transitioning to renewable electricity. We continue to explore other levers to maximise impact this decade and are selecting technologies for sustained decarbonisation beyond 2030 and towards net zero. Industry-wide decarbonisation requires removal of systemic and technical roadblocks:

- Sufficient aluminium recycling capacity.

- Increased recycling rates (through systems like DRS or EPR).

- Industry-wide standardisation and investment in innovation for highly recyclable beverage can ends.

We continue to collaborate with suppliers, customers, and industry associations to advance beverage can decarbonisation.

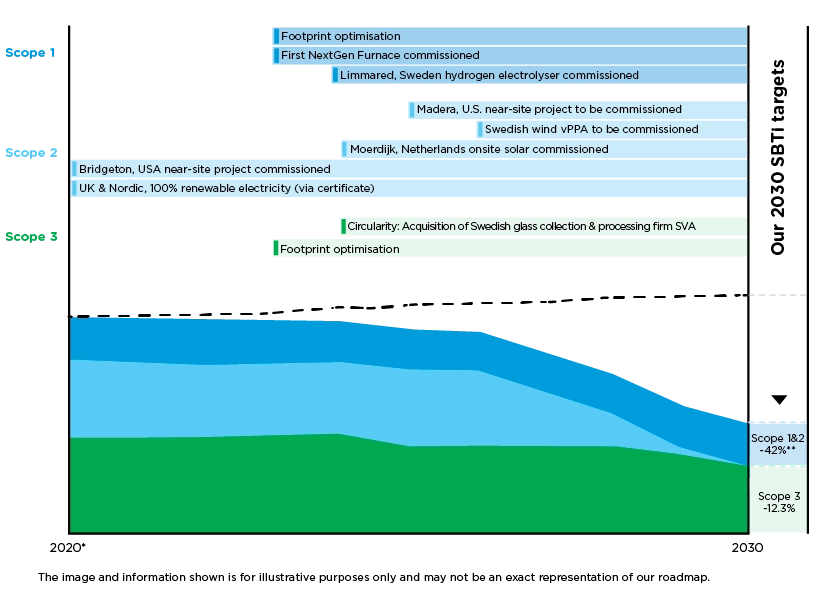

AGP roadmap towards our science based targets

We aim to achieve our 2030 emissions targets through a broad range of actions outlined below while setting the foundations for further decarbonisation beyond 2030.

*Baseline figures for emissions are from 2020

**Scope 2: 100% renewable electricity by 2030

—— Projected business as usual

Our significant investments, and the progress we’ve achieved, highlight AGP’s unwavering commitment to sustainability. System-wide decarbonisation demands collective, holistic efforts that extend beyond the capabilities of any single bottle maker. We call for collaboration across industries, governments, and society to accelerate an equitable path toward decarbonisation through, but not limited to, the following actions:

- Increased grid capacity to enable low carbon technologies based on renewable electricity.

- Increased recycling rates to increase cullet availability and cullet use in our facilities.

- Renewable electricity at competitive pricing.

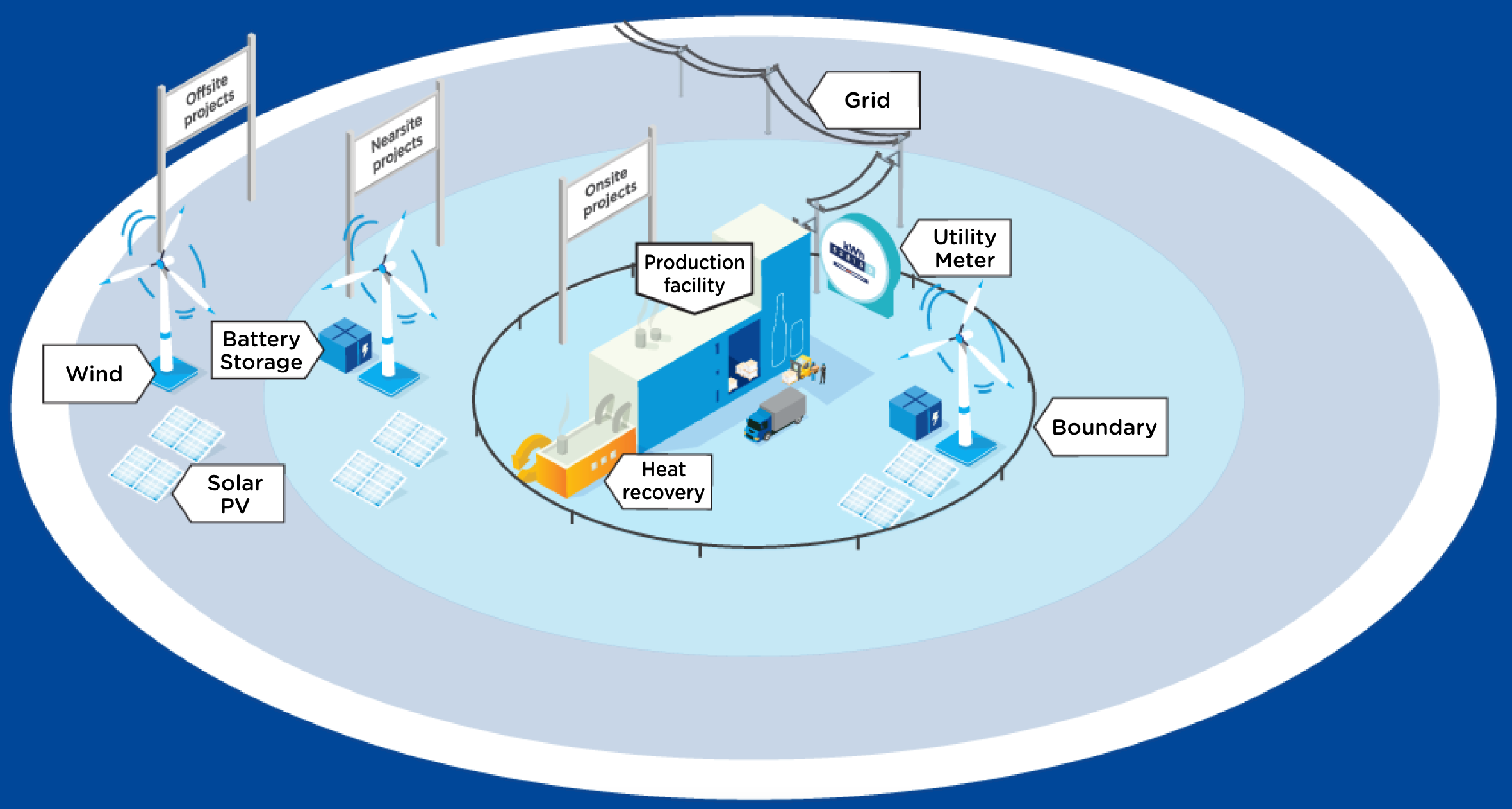

Renewable electricity

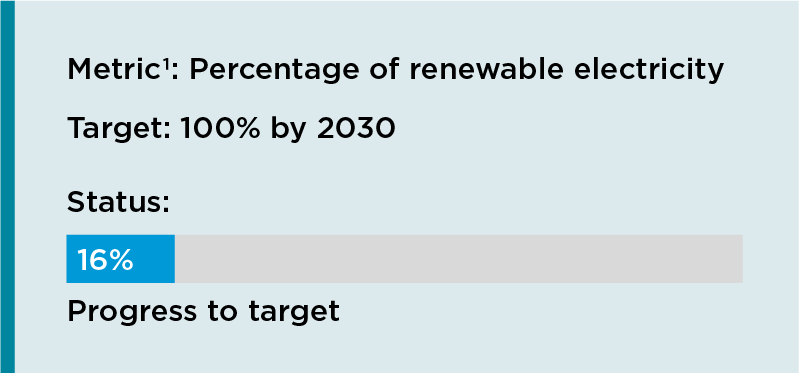

Our goal is clear: achieve 100% renewable electricity by 2030. We are committed to sourcing renewable electricity in a way that delivers real impact.

We believe our approach supports the growth of clean energy infrastructure, aligning with our efforts to reduce our carbon footprint and transition to a more sustainable energy future – benefiting our customers, operations and the environment.

2023 AMP status to targets

2023 AGP status to targets

¹ The Research Institute of Sweden (RISE) provided limited assurance of the acquisition, processing and aggregation of the quantitative data necessary to calculate the principal 2023 environmental and health & safety KPIs reported.

We pursue renewable electricity projects across a range of solutions, including offsite, near-site, and onsite initiatives. As part of this strategy, we prioritise additionality – supporting projects that add new renewable electricity capacity to the grid.

Ecology

Water

Water is a precious resource and essential to the wellbeing of the communities we live and work in, our customers’ success and our daily operations.

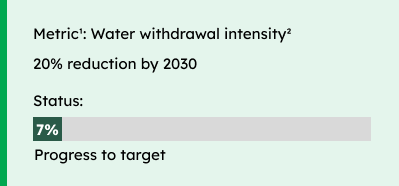

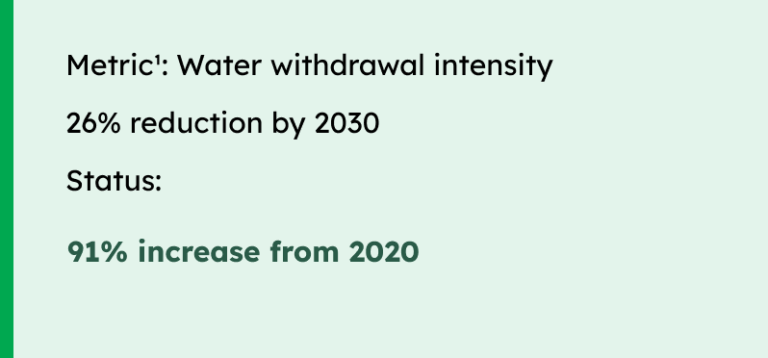

AMP aims to reduce water intensity across its operations by 20% and AGP by 26% by 2030 – all while maintaining the highest standards of quality and innovation.

We utilise water risk assessment tools to identify and prioritise investments in areas most at risk, ensuring we address critical needs and minimise our negative impact. Read more in our latest sustainability report.

2023 AMP status to targets

2023 AGP status to targets

¹ The Research Institute of Sweden (RISE) provided limited assurance of the acquisition, processing and aggregation of the quantitative data necessary to calculate the principal 2023 environmental and health & safety KPIs reported. ² Intensity metrics shown include can body production facilities only (excluding Huron, Ohio – since this facility produces both cans and ends), as water and VOC emissions from ends production is insignificant.

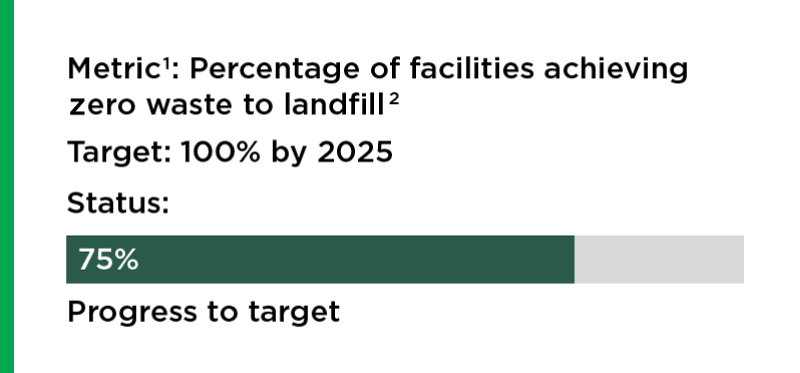

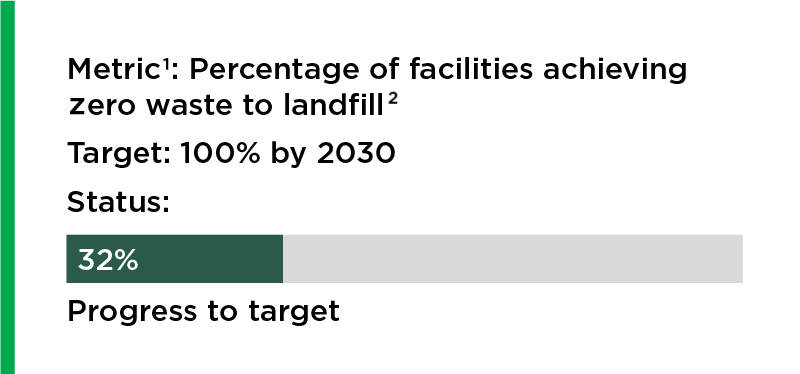

Waste

AMP is targeting zero waste to landfill (ZWTL) by 2025, while AGP is working toward ZWTL by 2030. Our goal is for all production facilities to divert at least 95% of operational waste, where permitted by regulation, away from landfill – ensuring materials are reused, recycled, or recovered wherever possible.

2023 AMP status to targets

2023 AGP status to targets

¹ The Research Institute of Sweden (RISE) provided limited assurance of the acquisition, processing and aggregation of the quantitative data necessary to calculate the principal 2023 environmental and health & safety KPIs reported. ² Zero waste to landfill for operational waste streams, where allowed by regulation.

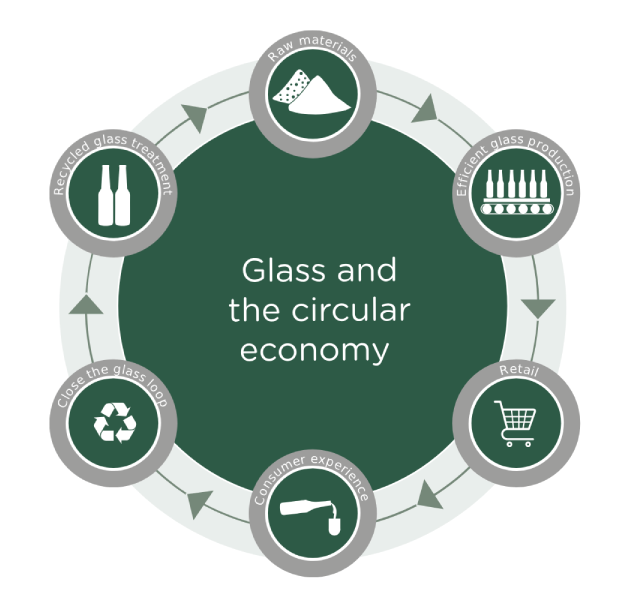

Circularity

Our materials

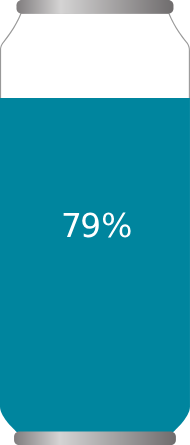

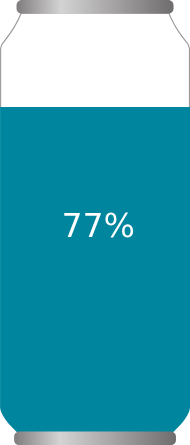

Metal and glass are both infinitely recyclable, with very minimal loss in quality, making them a perfect example of a circular economy product. In support of our emissions targets. we aim to use less virgin raw material, increase recycled content and lightweight our containers without sacrificing quality.

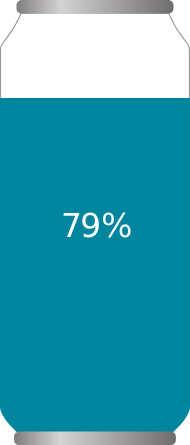

Recycled content % – 2023¹

The use of recycled aluminium reduces the energy consumption by over 90% compared with the alternative of producing aluminium cans from its virgin source.

Europe

North America

South America

Global

¹ Industry has aligned on a definition of recycled content, which will standardise how the recycled content % is calculated. Data for 2024 onwards will be based on the new industry aligned Beverage Can Recycled Content (BCRC) methodology.

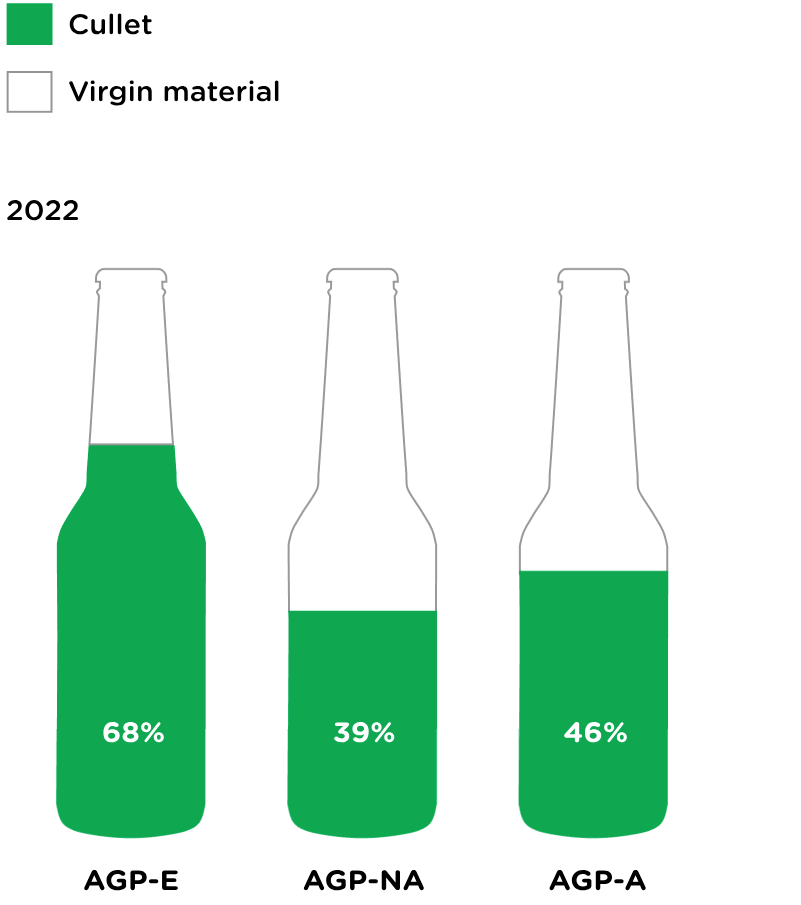

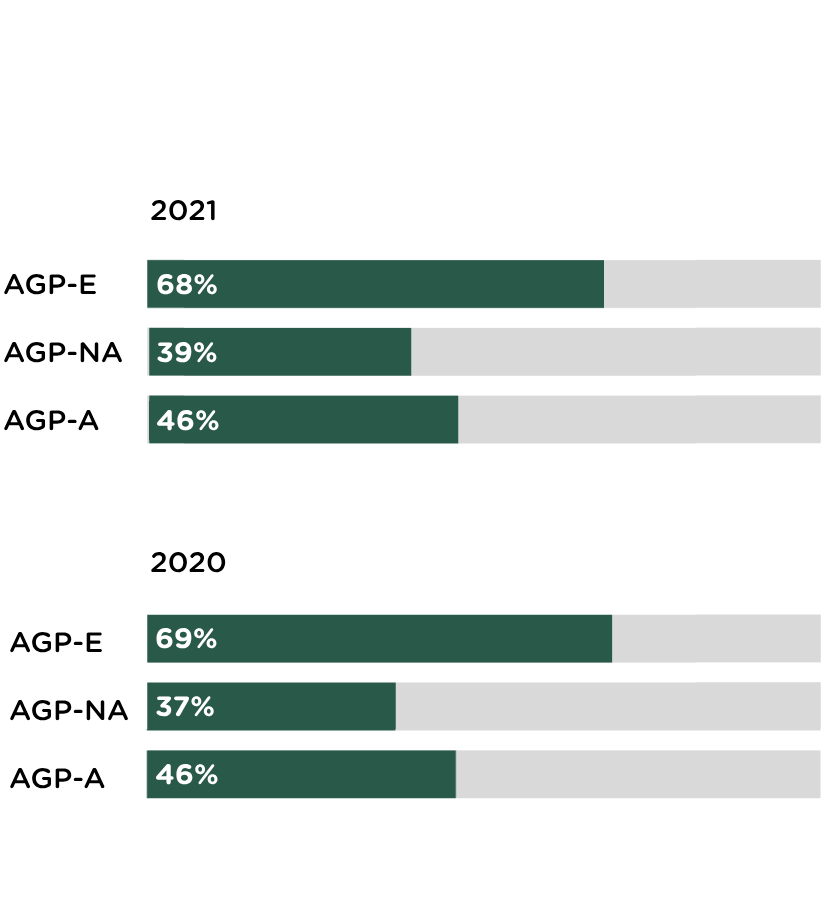

Cullet percentage of glass¹

¹ Cullet is defined as the combined total of internal and external cullet, including post-consumer recycled content.

At AGP, maximising recycled glass (cullet) is central to our efforts to lower energy use and emissions. As we drive greater cullet integration, we carefully balance quality and cost to ensure we continue delivering the premium products our customers expect.

Collaborating for a circular economy

We work very closely with our trade associations to present a unified voice to address key issues and advocate for policies and practices that encourage recycling and environmental responsibility for metal and glass packaging.